How to Choose the Right Cold Shrink Tube: A Comprehensive Guide

What is a Cold Shrink Tube?

A cold shrink tube is a tubing used to insulate and seal connections in electrical and telecom applications. It shrinks without heat, automatically contracting when the inner core is removed to form a tight, waterproof, and weather-resistant seal. This provides excellent electrical insulation, mechanical protection, and environmental sealing.

Cold shrink tubes are ideal for communication, coaxial, and medium to low-voltage power cables, offering a quick and reliable solution compared to traditional heat shrink tubing.

Benefits of Cold Shrink Tube

- Installs without heat, saving time and reducing the risk of damage to cables and components, while taking up less space than gel seal enclosures.

- Conforms uniformly around cables or components, providing a tight and secure seal.

- Resists UV radiation, ozone, and extreme temperatures, ensuring long-lasting performance.

- Offers excellent electrical insulation, mechanical protection, and environmental sealing.

How to Choose Cold Shrink Tube?

Choosing the Right Size

When selecting a cold shrink tube, consider the following:

- Pre-Shrink Size: Ensure the tube’s pre-shrink size is large enough to fit over the largest component, such as a connector, with extra space for removing the plastic core.

- Length: Choose a length that fully covers the area you want to protect. A longer length can offer better sealing.

- Shrink Size: Confirm that the tube can shrink tightly enough to create a watertight seal around the object.

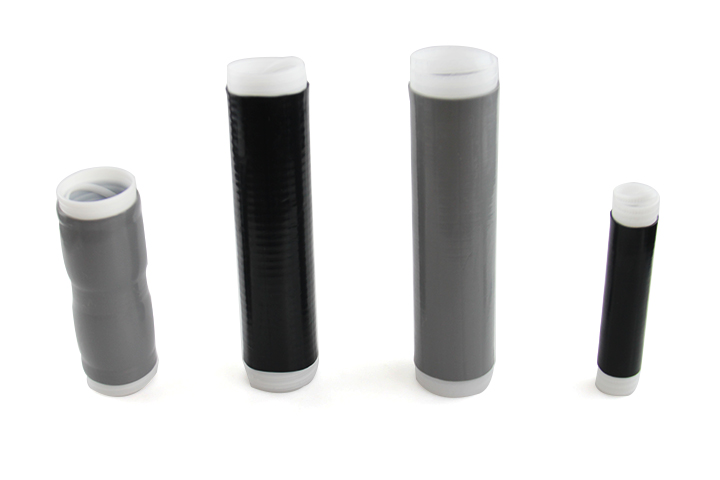

Silicone Cold Shrink Tubes vs EPDM Cold Shrink Tubes

Silicone Cold Shrink Tube

- Shrink ratio: 4:1

- Temperature: -60℃~ +200℃

- Elongation at Break: >800%

- Tear strength: ≥40KN/m

- Resistant to ozone aging, UV, salt spray corrosion

- Made in a variety of colors

- Used without foam strip

Detailed Applications for Silicone Cold Shrink Tubes:

- RF Connections: Ideal for insulating and sealing RF connectors, especially in outdoor environments where extreme temperatures and UV exposure are concerns.

- Communication Towers: Used on antennas and tower installations, providing long-lasting protection against environmental factors such as ozone, UV radiation, and salt spray corrosion.

- High-Temperature Environments: Suitable for applications requiring stability across a wide temperature range (-60℃ to +200℃), making it perfect for use in industries like aerospace, automotive, and electronics.

- Corrosion-Prone Areas: Effective in environments with exposure to corrosive elements, ensuring reliable performance and longevity.

EPDM Cold Shrink Tube

- Shrink ratio: 3:1

- Temperature: -40℃~ +90℃

- Elongation at Break: >720%

- Tear strength: ≥30KN/m

- Resistant to puncture, piercing, wearing

- Usually in black color

- Usually used with foam strip

Detailed Applications for EPDM Type Cold Shrink Tubes:

- Industrial Environments: Ideal for sealing and insulating components in harsh industrial settings, particularly where equipment is exposed to mechanical stress, abrasion, and puncture risks.

- Machinery Interiors: Suitable for use inside machinery, where protection against wear and tear is critical. The EPDM material’s resistance to punctures and piercings makes it a reliable choice for safeguarding cables and connectors within mechanical assemblies.

- High-Impact Zones: Applied in areas prone to frequent collisions or abrasive contact, providing durable protection and extending the life of the components.

- Electrical and Mechanical Assemblies: Frequently used to protect and insulate connectors in electrical and mechanical assemblies where consistent performance under moderate temperatures is required.

How to Install Cold Shrink Tube?

Installing a cold shrink tube is a straightforward process, but it requires careful attention to ensure proper application. Here’s a step-by-step guide:

Prepare the Cable or Object:

Ensure that the surface of the cable or object you’re covering is clean and dry. Wipe it down with a cleaning cloth or wipes to remove any dirt, oil, or moisture.

Step 1, Select the Correct Cold Shrink Tube:

Choose the appropriate size of cold shrink tube based on the diameter of the cable or object.

Step 2, Position the Cold Shrink Tube:

Slide the cold shrink tube onto the cable or object.Make sure that the tube covers the area that needs protection or insulation.

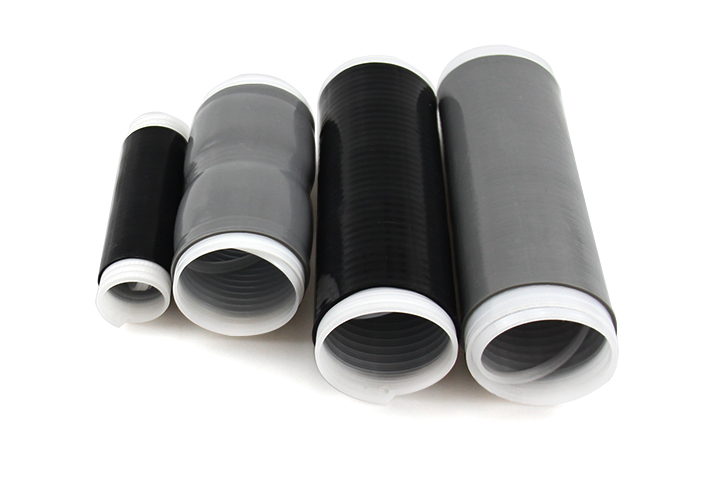

Step 3, Remove the Inner Core:

Cold shrink tubes come with an inner plastic core that keeps them expanded. Hold the cold shrink tube in place with one hand while slowly pulling out the inner core with the other hand. The tube will start to shrink and contract onto the cable as the core is removed.

Step 4, Check the Fit:

Once the tube has fully shrunk, check to make sure it is securely in place and has formed a tight seal around the cable or object. The tube should be smooth and free of wrinkles.

Step 5, Trim the Excess (if necessary):

If there is any excess tubing extending beyond the needed coverage area, you can trim it carefully with a utility knife or scissors.

Step 6, Inspect the Installation:

Finally, inspect the installation to ensure there are no gaps or loose sections. The cold shrink tube should fit snugly and provide a protective seal.

Tips:

Work Carefully: Take your time during installation, especially when removing the inner core, to avoid misalignment or errors.

Use the Right Size: Always use the correct size cold shrink tube to ensure proper coverage and sealing.

Maxdao Cold Shrink Tube Product List

Explore our wide range of cold shrink tubes designed for various electrical and telecommunications applications.

For specific requirements or unique sizes, Maxdao offers custom solutions to fit your special needs.

| Item No. | Typical RF Application | Connector Size | Cable OD | Color |

| SMA | 8mm(0.32”) | 4.9mm(0.19”) | Black | |

| TNC | ||||

| 6002887 | Cable connection | 15mm(0.59”) | 6.4mm(0.25”) | Black |

| 6005727 | N type | 20mm(0.79”) | 6.4mm(0.25”) | Black |

| 6008634 | 4.3-10 | 25mm(0.98”) | 6.4mm(0.25”) | Black |

| 6008526 | 4.3-10 | 28mm(1.10”) | 7mm(0.28”) | Black |

| 6005718 | 4.3-10 | 35mm(1.44”) | 10mm(0.39”) | Black |

| 6006422 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Black |

| 4.3-10 | ||||

| 6008041 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Yellow |

| 4.3-10 | ||||

| 6006422 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | White |

| 4.3-10 | ||||

| 6008043 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Purple |

| 4.3-10 | ||||

| 6008044 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Red |

| 4.3-10 | ||||

| 6008045 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Blue |

| 4.3-10 | ||||

| 6008746 | 7/16 DIN | 40mm(1.57”) | 12mm(0.47”) | Grey |

| 4.3-10 | ||||

| 6005728 | 7/16 DIN | 44mm(1.73”) | 12mm(0.47”) | Black |

| 4.3-10 | ||||

| 6008318 | Cable connection | 60mm(2.36”) | 6.4mm(0.25”) | Black |

Contact Us

If you’re unsure which size of the cold shrink tube is best for your application,our team are ready to provide advice. We also offer other types of waterproof sealing materials. Please feel free to contact us at any time. Contact us for more info@maxdao.com