FAQ about Hoisting Grip, Support Grip, Approximate Break Strength, Safe Load, Safety Factor etc

Learn about Hoisting Grip, Support Grip, Approximate Break Strength, Safe Load, Safety Factor and more.

What are hoisting grips used for?

Hoisting grips are a type of support grip and are used with safety ropes to safely lift cables onto the tower and mechanically connect them to antennas. When the cables are in place and secured to tower components, hoisting grips provide support to the cable. Closed grips are used only on the end of cables and provide permanent support when the cable is connected to the tower. Open mesh grips can be used anywhere along the cable, as additional cable support, or removed.

What are support grips?

Support grips are used to support the weight of cables when they are hung vertically, horizontally, or at an angle. Without support, the weight of the cable can cause stress or breakage at connection points, resulting in transmission failures. Support grips can also absorb additional stress caused by bending, vibration, expansion, and contraction. They come in various styles to meet the suspension needs of different cables and can also be used to support metal rods, hoses, or cables. They have a wide range of applications.

What should be taken into consideration when using hoisting grips?

When using hoisting grips:

- Do not use one hoisting grip to lift two or more cables. This helps prevent the grip from breaking and the cable falling.

- Do not use hoisting grips to lower the cable. Wrapping the cable may cause the grip to loosen, which may cause the cable to fall.

- Do not reuse hoisting grips. Used hoisting grips may have lost their elasticity, or become stretched or brittle. Reusing them may cause the cable to slip or fall.

- Select the appropriate hoisting grips to ensure proper gripping force.

How is the breaking strength of hoisting grips determined?

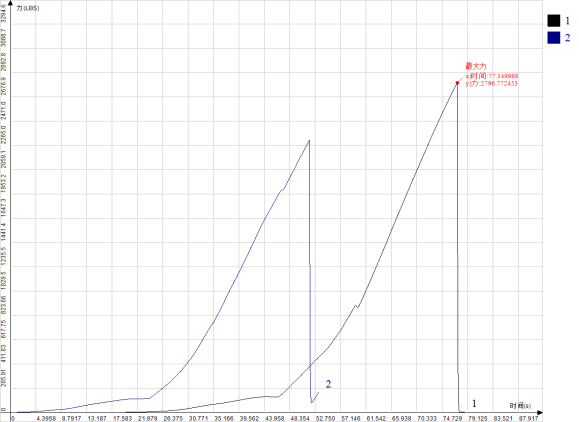

The breaking strength is determined through actual direct tension testing performed on new and unused grips in the laboratory. The breaking strength is determined by the material of the grip, the diameter of the wire rope used, and the number of wire rope strands.

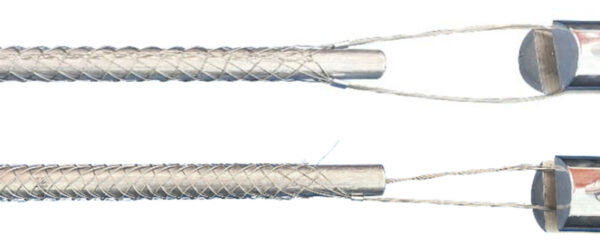

Tensile Testing Machine

Test Photo

Test Result

What is the working load of Hoisting Grips?

The working load is the maximum weight that can be safely carried by the grip when lifting or suspending without worrying about the grip breaking. To ensure safety, appropriate safety factors are established to determine the working load.

What is the safety factor of Hoisting Grips based on?

The safety factor increases the reliability and safety of the product by considering possible risks, uncertainties, or unexpected factors, and reduces personnel injury or equipment failure. The safety factor is usually marked as X:1. It is determined based on various factors, such as tension, diameter, movement, the number of objects being gripped, gripping surface, and accessories used, which vary with each application. Other variables such as wear, corrosion, or previous use or misuse also need to be considered. Users should replace the grip when necessary based on the specific application and conditions. For applications with uncertain conditions that may cause injury to personnel or property, a larger safety factor should be used. The specific safety factor is determined by the end-user based on their acceptance level.

What is the safety factor of Maxdao Hoisting Grip?

Maxdao’s hoisting grips are designed based on the safety factor 5:1

Contact Us

If you’re unsure which type of the hoisting grip is best for your application, our team are ready to provide advice. We also offer other types of support grips. Please feel free to contact us at any time. Contact us for more info@maxdao.com