Delivering Products Customers Can Trust

With Maxdao, you can rest assured that you are partnering with a company at the forefront of the industry. We adhere to strict standards and regulations, ensuring that every product we deliver meets the highest quality benchmarks.

- Cutting-edge technology: Maxdao leverages cutting-edge technology in every phase of the manufacturing process from design to production. Our state-of-the-art equipment and software enable us to consistently meet precise manufacturing requirements.

- Expert craftsmanship: Our team of highly skilled professionals is the backbone of our manufacturing process. Our attention to detail, knowledge, and dedication to quality help our products exceed customer expectations.

- Stringent material selection: We source only the finest materials for our products. Our rigorous material selection process ensures durability, longevity, and performance. With our network of certified suppliers, we gain easy and fast access to durable and safe materials to ensure efficient and cost-friendly production.

Our rigorous quality control process

We use innovative technology to test the performance of our wireless site components. Throughout each step of production, we maintain consistent quality and performance by performing a variety of tests.

High/Low-Temperature Test

Since our wireless site components need to tolerate shifting weather conditions, our accredited laboratory conducts high/low-temperature testing to document product performance under adverse conditions. Components that pass this rigorous testing demonstrate their capability to adapt and function well in diverse environments.

Vibration Test

We conduct vibration tests prior to production to ensure that components maintain their shape and performance. This allows us to determine material durability, identify defects, and make improvements before material enters the manufacturing process.

Flame Retardant Test

We apply different flame retardant chemicals to our products to find the right protection for each component that also allows safe use. This testing reduces fire hazards and protects against intense heat.

Salt Spray Test

In compliance with SUS304 standards, we conduct salt spray tests to determine how our components resist corrosive chemicals. Consistent testing helps ascertain how our wireless site components work close to saltwater and at high elevation.

Waterproof Test

To meet high IP ratings and waterproofing standards, we carry out tests to reduce hazard risk and failures while confirming the product’s ability to withstand corrosion, rust, and other forms of degradation. Our accredited laboratory has the equipment needed to measure the waterproof performance of our products.

Tensile Test

Every wireless site component is tested in our certified laboratories. We measure each product’s ability to perform under high levels of tension. Through our tests, we are able to confirm that the components possess high tensile strength and rarely break down, reducing any need for maintenance.

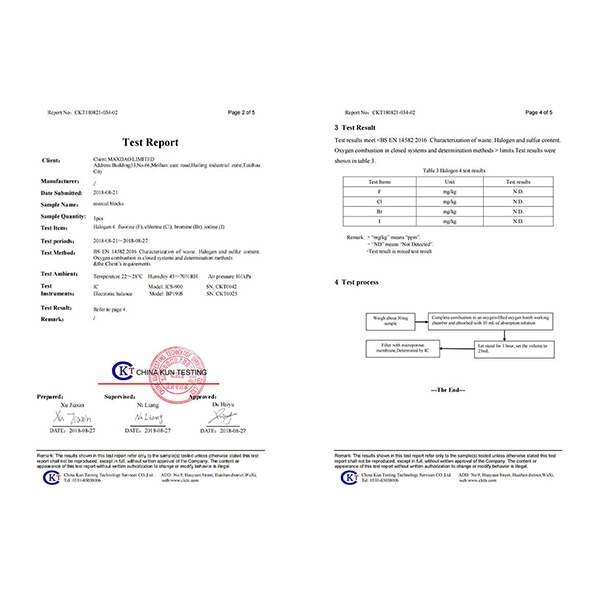

Halogen Test

To deliver high conductivity and improve electrical flow, we conduct tests to detect concentrations of halogens in our products. This testing guarantees overall safety from harsh chemicals and identifies the amount right for your application.